We're professional tomato ketchup production line manufacturers and suppliers in China, to buy or wholesale

ketchup production line from our factory. For quotation or if you have any questions, contact us now for customized tomato processing line and price.

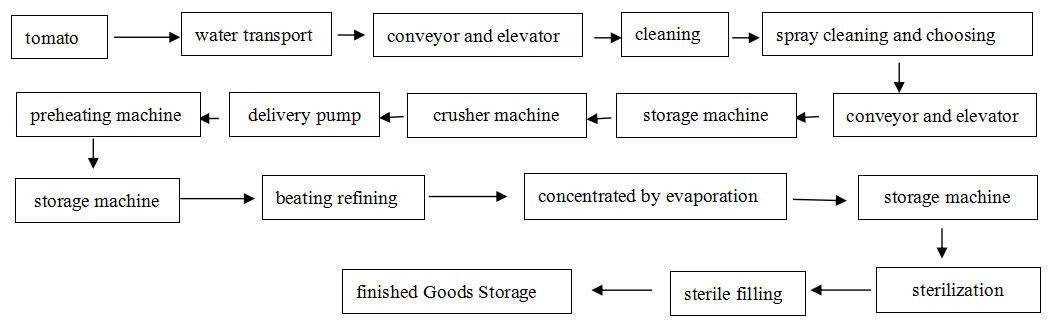

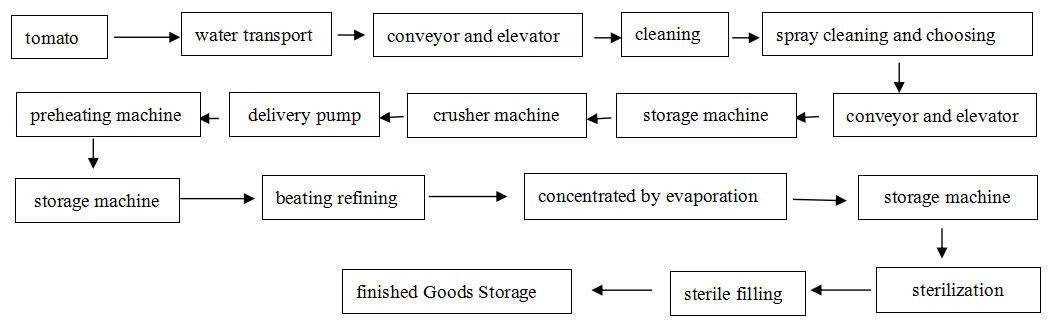

Technological Process

System Description

The whole tomato sauce production line and related equipment is according to the principle of international high quality standard for cold/hot break tomato sauce with different concentration levels of design.

Cold /Hot broke tomato sauce production line mainly includes skirt board, cleaning machine, choose fruit machine, crusher machine, preheating machine, beating machine, evaporator, storage tank, the sterilization machine and aseptic filling equipment. Under aseptic condition of tomato sauce can be reprocessed in the future deployment of ketchup, sauce, tomato sauce, and so on.

Equipment Description

|

Raw material preparation

◎ Acquisition of a large number of tomato, transportation to the processing plant; ◎ The tomato is discharged into the soaking tank,self-made soaking pool for cement; ◎ Each channel is equipped with a material elevator ; ◎ According to the production capacity and plant design.

|

Elevator、cleaning and conveyor system

◎Tomato through the water delivery process and cleaning; ◎Spray cleaning device and to sediment device; ◎Single-channel processing capacity of 10-40 T / hour; ◎Water tank can be set according to the production capacity and plant design.

|  |

|

Choosing fruits、spray cleaning system

◎ Roller conveyor, 360℃ revolve; ◎ Waster conveyor device and spray cleaning device; ◎ Each processing capacity of 10-40T / hour; ◎ According to the production capacity and plant design;

|

Cold crushing conveyor system

◎ Tooth broken, feed for automatic feeding system; ◎ With the slurry storage tank and governor discharge pump; ◎ Door Security protection and the level of the slurry-bit security protection control; ◎ Each processing capacity of 10-40T / hour; ◎ According to the production capacity and plant design;

|  |

|

Softening enzyme inactivation system

◎ Bundle heating structure; ◎ With automatic temperature control, low temperature reflow device; ◎ The external is equipped with insulation layer; ◎ Each processing capacity of 10-40T / hour; ◎ According to the production capacity and plant design;

|

Beating Refiner system

◎ Structure:high speed rotary dial plate separation refining; ◎ Mesh size: φ0.4-φ1.5mm (selection); ◎ The adjustment dial plate angle, mesh size, speed, effective separation of different kinds of material; ◎ Automatic separation of the fruit pulp and pomace (skins, seeds); ◎ Processing capacity:single channel 10-15T/hour, dual channel 20-30T/hour.

|  |

|

Circulation evaporation system

◎ Composed of the evaporator, separator, condenser, circulating pump efficiency between pumps or too material control valve, vacuum and drainage system, operating platform, electrical instrumentation and control cabinets and valves, piping and other system; ◎ Cycle divided into double, three, four, five, six effect evaporator; ◎ Circulating can make the viscosity larger easy flow of material liquid evaporation; ◎ Access to materials, liquid level and the required concentration can be controlled; ◎ Evaporation of water:8T/h-110T/h;

|

Tube sterilization system

◎ This machine is mainly used in a variety of enrichment material sterilization and cooling process; ◎ This machine consists of material storage tank, hot water tank, pump, casing heat exchanger, PLC control system, control cabinet, the steam inlet system, valve, sensor switch, etc; ◎ Temperature:sterilization≤125℃,ejection of compact≤35℃(controlled automatically); ◎ Have a reflux device at low temperature; Processing capacity:1-8T/hour(adjust the speed);

|  |

|

Aseptic Filling(bags)

◎ Single or double; ◎ By aseptic filling systems, weight measurement systems, roller conveyor system, computer PLC control system, operating platform, are all stainless steel; ◎ Steam injection mode to be sterilized to ensure that the filling chamber is always out of the aseptic condition of the bag and filling machine; ◎ After filling, the product can be stored at room temperature for more than a year; ◎ Synchronization and tube sterilization machine CIP system (self-cleaning)) and SIP (self-disinfection system); ◎ Processing capacity:1-8T/hour;

|

Packaging products (sauce)

◎ Packaging:Enclosed sterile aluminum foil paper bag; ◎ Iron drum labeled(Content according to the requirement); ◎ Weight:220L(about 230kgs-240kgs) iron drum; ◎ Four durms/pallet , eighty drums/20’GP;

|  |

Scope of application

Suitable for (tomato sauce)production of 28-30%,30-32%,36-38% high viscosity (viscosity 5-9),

28-30%,30-32%,36-38% low viscosity (viscosity 3-5).

Raw material:200 T/day to 3000 T/day.

System composition

Elevator machine、cleaning machine、choosing machine、crusher machine and skirt board、hot/cold broke preheating、beating machine, evaporator, storage tank, the sterilization machine and aseptic filling equipment.

Main features

☆ Beautiful appearance, reasonable design of a full set of system stable operation, high efficiency and energy saving, low steam consumption。

☆ Material storage pool and product savepoint is not required in the processing 。

☆ Uninterrupted cycle process。

☆ According to customer's technical requirements, choose cold or hot breaking。

☆ Forced circulation evaporator, the viscosity of tomato sauce to flow easily evaporated, concentrated short time。

☆ Evaporator evaporation temperature is low, Heat is fully utilized, mild tomato sauce is heated, the tube is heated evenly and heat transfer coefficient is high, can prevent the phenomenon of "dry wall”。

☆ Using the special structure of the condenser, and in normal operation in the case of the cooling water temperature 30 ℃ even higher。

☆ Continuous access to materials, level with the desired concentration can achieve self-control。

☆ Tube sterilization and aseptic filling combination synchronized CIP system (self-cleaning)) and SIP (self-disinfection system);

☆ No product legacy into the cooling tower。

☆ With advanced technology to maximize the energy savings。

☆ Integrated water cycle system, the lowest consumption。

☆ Complete supervision system, equipped with a control room to monitor each stage of the process.

The implementation of public works

1、 Cable, bridge, slot, power wire, electrical accessories: according to user's workshop, installed by users themselves;

2、 Other ancillary works

◎ Cement soaked collection system, installed by the user;

◎ Weeding equipment, installed by the user;

◎ Cooling water circulation system,installed by the user;

◎ Compressed air station,installed by the user;

◎ Steam generator,installed by the user;

◎ Steam piping, water pipeline, electrical lines, etc. according to the user plant design,installed by the user;

Tomato ketchup production line Manufacturer

Elite Food Machinery focuses on providing high-quality pharmaceutical processing equipment for fruits and vegetables, and excellent service with years’ expertise. Elite Food Machinery provides you with wholesale, customization, OEM & ODM service...

If you have any questions about tomato ketchup production line, ketchup production line, tomato processing line, tomato paste processing line, tomato paste production lines, please don't hesitate to contact us at any time. We will provide detailed information and technical support about the features, specifications, solutions and customization options of pharmaceutical processing equipment for fruits and vegetables... Welcome you to visit our factory!

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu