We're professional bagasse pulp making machine manufacturers and suppliers in China, to buy or wholesale bagasse products manufacturing machines from our factory. For quotation or if you have any questions, contact us now for customized sugarcane bagasse pulp making machine and price.

Purpose

1. This machine is the belt juicer of our company, which is digested and absorbed by the most advanced German “Flottweg” company in the world. It has been carefully developed and is an efficient extraction equipment. It is the key equipment related to the juice yield in the production of fruit juice and vegetable juice。

2. It can be widely used in the juice industry of berries, nuts and various vegetables. The equipment adopts multi-stage bending rod and multi-stage pneumatic roller to press, which has large pressing force and high juice yield.

3. At the same time, it has the characteristics of high energy-saving automation, automatic feeding and discharging, continuous operation, strong universality, full pressure filtration, low water content filtration of filter cake, convenient operation and maintenance, etc. it is a kind of juicing equipment with high juice yield.

4. Using this equipment can increase the juice yield by 20-30% and 70-75% (depending on the raw materials), greatly reduce the production cost and improve the economic benefits of the enterprise.

Structural features

1. The machine is composed of frame, upper and lower drive shafts, deceleration drive assembly, press roll combination, press filter belt, cleaning belt assembly, feed assembly, tension device, belt deviation correction assembly, pressure boosting device, safety protection device, gas electric control device, cleaning water filtering device, etc.

2. Transmission: the high torque reducer can realize continuous and stable power speed regulation through frequency conversion.

3. Filter pressing belt: it is made of polyester nylon yarn by warp and weft knitting, with the characteristics of acid and alkali resistance, food hygiene, easy juice, non water absorption, high strength, etc.

4. Press roll: according to the logistics trend, the radius of the press roll contacted is getting smaller, the curvature is getting larger, the L-shaped press roll structure is unique and reasonable, and the configuration of various press rolls, including stainless steel tube processed roll, rubber lined roll, and the size distribution is reasonable.

5. Tension of pressure filter belt: the rubber air spring is used for automatic tension, which is not only stable but also avoid overload, safe and reliable, and equipped with pressure relay, which can automatically and safely stop the machine and realize the whole process automation.

6. Cleaning of filter press belt: wedge type (arc type) filter screen is used for automatic filtering, slag discharging, equipped with high-pressure pump and jet device, which can conveniently clean the filter press belt while filtering, which has good juice effect and saves energy.

Technical parameters

Type | DYJ-3 | DYJ-5 | DYJ-10 | DYJ-15 | DYJ-20 |

Capacity | 3T/h | 5T/h | 10 T/h | 15T/h | 20 T/h |

Track line speed | 0 -0.1m/s |

The main drive speed | 0-9r/min | 0-9r/min | 0-9 r/min | 0-5 r/min | 0-5 r/min |

Power | 2.2kW | 3 kW | 4 kW | 5.5 kW | 5.5 kW |

Flushing pump power | 7.5 kW | 11 kW | 15 kW | 15×2 kW | 15×2 kW |

Flushing pump flow | 10m3/h | 14 m3/h | 16 m3/h | 16×2 m3/h | 16×2 m3/h |

Flushing pump head | 120m | 165 m | 189 m | 189×2 m | 189×2 m |

Reflux pump power | 2.2 kW | 2.2 kW | 2.2 kW | 3 kW | 3 kW |

Reflux pump flow | 10m3/h | 14 m3/h | 16 m3/h | 32 m3/h | 32 m3/h |

Reflux pump head | 20m | 20 m | 20 m | 20 m | 20 m |

Distributing roller power | 0.18 kW | 0.18 kW | 0.37 kW | 0.37 kW | 0.37 kW |

Distributing thickness | 25~30mm |

Compressed air consumption | 120L/ min |

Compressed air pressure | 0.7 MPa |

Feeding port height | 1900mm | 1900 mm | 1920 mm | 1920 mm | 1920 mm |

Dimension (mm) | 3090×1620 ×2000 | 4000×2000 ×2500 | 4850×2680 ×2570 | 5310×2970 ×2570 | 5310×3470 ×2570 |

Technical parameter index of belt squeezing of GKD company in Germany |

Press belt size (mm) | 9100×800 | 12040×1200 | 14320×1750 | 17300×2000 | 17300×2500 |

Model of filter belt | 913 | Permeable rate | 1550L/dm2 min |

Filter belt material | Polyester | Warp diameter | 0.50mm or 0.65mm |

Setting treatment | Heat setting | Warp count | 15 /cm 38 /inch |

Weaving method | Twill weave | Weft diameter | 0.70mm or 0.80mm |

Unit weight | 1360g/m2 | Weft count | 6 /cm 15 /inch |

Belt thickness | 2.4mm | Strength radial latitudinal | 235KN/m 249KN/m |

Ventilation rate | 2580L/m2 sec | Colour | Dark blue |

Our company reserves the right to interpret the above technical parameters

Main structure principle

1. During operation, the refined raw materials (solid-liquid mixture) are continuously fed into the hopper by a screw pump (the material takes up an adjustable bandwidth), and the inner and outer two ring-shaped filter belts are driven by the driving roller and evenly distributed by the pressing roller.

2. In the wedge-shaped area of the lower bend, the inner and outer filter belts move according to their respective circuits, and bypass a number of press rollers with different diameters, a large amount of water is slowly pressed out, forming a rate cake that can be pressed.

3. In the pressing area, a pressing roller with an "L" type strip will press out the water and ensure that the water is pressed out from both sides.

4.After that, the diameter of the pressing roller decreased, and the filter belt was in the "s" shape, resulting in the increasing shear force of the surface pressure.

5.Under the tension of the filter belt, the outer filter belt produces pressure on the material to squeeze out the juice in the material. As the diameter of the pressing roller decreases gradually, the pressure on the material between the filter belts increases gradually, and the juice is discharged continuously.

6.In order to ensure the best dewatering effect, then the material bypasses the driving roller. Under the last two-stage pressing roller, there are two-stage rubber lined pressing rollers with different pressure to automatically pressurize the filter belt, further discharge the juice in the material and improve the juice yield

7.After the internal and external filter belts are separated, the dehydrated filter cake (fruit residue) on the working surface of the internal and external filter belts is scraped off by a wear-resistant material scraping device. (in order to improve the scraping effect and facilitate the cleaning of the pressing belt, the user can choose to add a brush to brush the residue further). Finally, our company introduces the foreign high-pressure solid cone convex nozzle to form a fan-shaped cross, and the flow rate is 4140 L / min when the pressure is greater than 1MPa In order to maintain the high pressure effect.

8.In the process of pressing, the upper and lower filter belts are equipped with a guide roller and a pneumatic valve for deviation correction, which can automatically correct the deviation of the filter belt through the push of the rubber air springs on both sides.

Juicing process

Juice extraction is divided into four steps:

1.Initial juice extraction: fresh fruit juice just delivered from the crusher enters the crusher through the speed regulating screw pump, at this time, most of the separated juice has automatically flowed out by gravity.

2.Low pressure extraction area: the juice moves forward between the two filter belts, and then is transported by a large-scale roller with "L" type surface strip. There is a certain pressure between the two filter belts. In this low-pressure area, juice is produced outwards and inwards by pressing roller.

3.High pressure extraction area: in the "s" shaped winding part, the pulp cake between the filter belts is continuously extracted by the squeezing roller, and the squeezing roller is gradually reduced, and the pressure is gradually increased. At last, one press roll on one side of the second press roll is pressurized by the air bag thrust to the upper roll, so that the juice can be squeezed out to the maximum extent.

4.After the juice is squeezed by high pressure, the fruit residue is discharged by the slag removal and scraping device. (in order to improve the scraping effect and facilitate the cleaning of the press belt, the user can choose to add a brush to brush the residue further). Finally, the press belt is automatically cleaned by the cleaning mechanism.

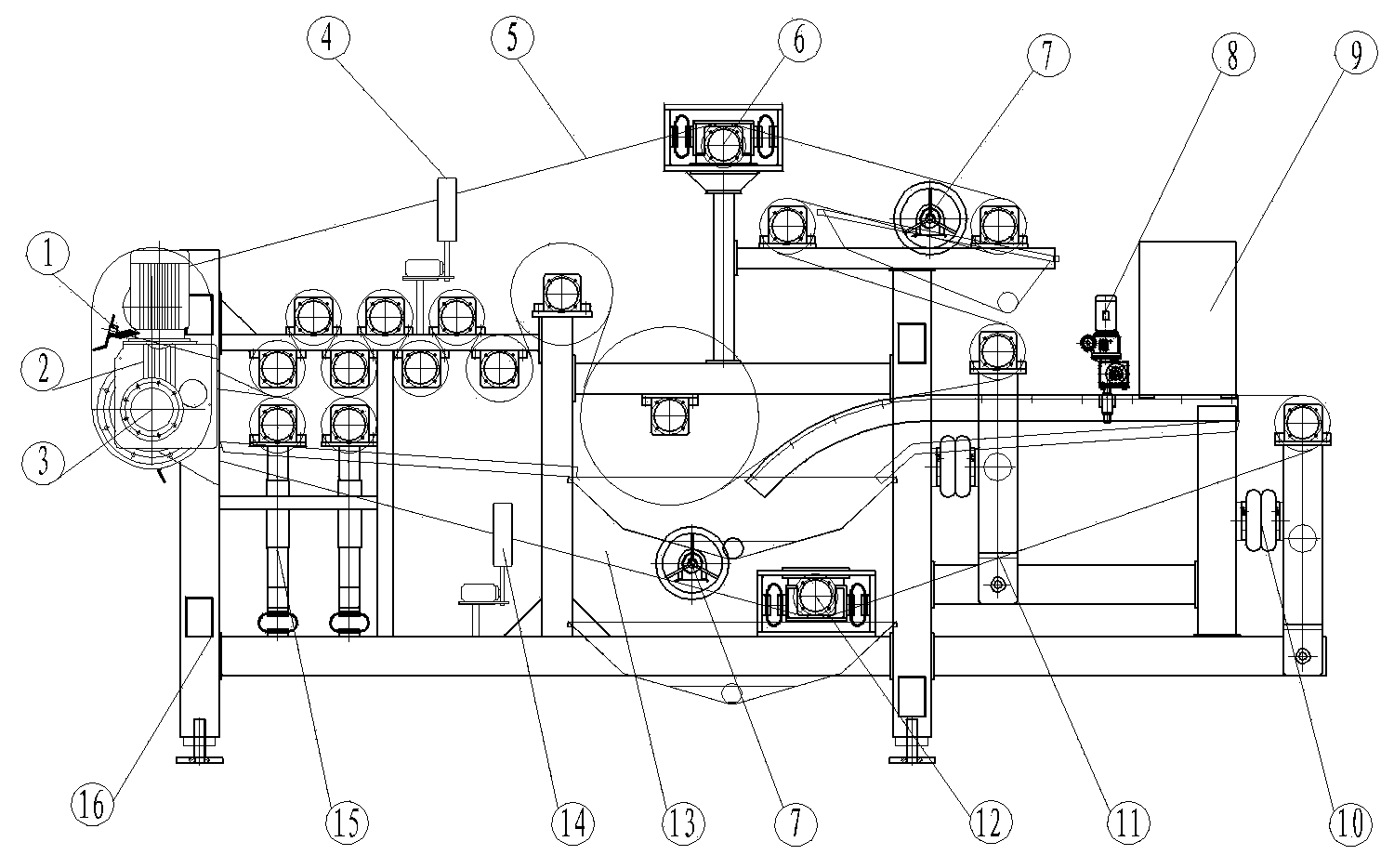

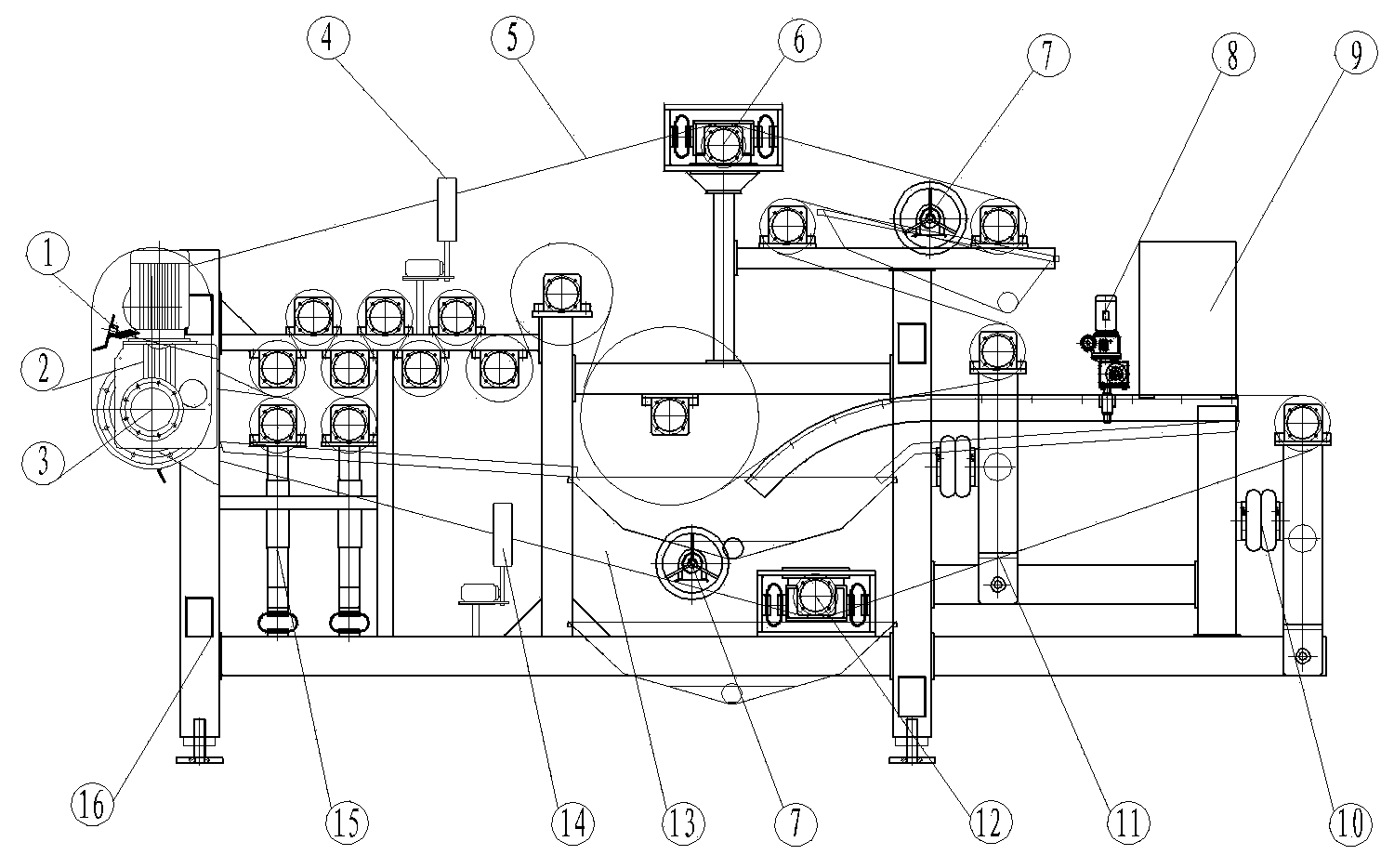

Drawing of the product

No. | Name | Material |

1 | scraper | nylon1010 |

2 | Main reducer | Helical gear |

3 | drive gear | MC nano nylon |

4 | Upper deviation valve baffle | SUS304 |

5 | Upper filter belt | Polyester |

6 | Upper rectifying roller | Rubber lined roller |

7 | High pressure flushing pipe | SUS304 |

8 | Speed reducer for fabric adjustment | Speed regulation of worm and gear |

9 | Feeder box | SUS304 |

10 | Tension air spring | rubber |

11 | Support frame of tensioning roller | SUS304 |

12 | Lower rectifying roller | Rubber lined roller |

13 | Lower filter belt | Polyester |

14 | Lower deviation valve baffle | SUS304 |

15 | Booster roller seat | SUS304 |

16 | frame | SUS304 |

Bagasse pulp making machine Manufacturer

Elite Food Machinery focuses on providing high-quality pharmaceutical processing equipment for fruits and vegetables, and excellent service with years’ expertise. Elite Food Machinery provides you with wholesale, customization, OEM & ODM service...

If you have any questions about bagasse pulp making machine, bagasse products manufacturing machines, sugarcane bagasse pulp making machine, please don't hesitate to contact us at any time. We will provide detailed information and technical support about the features, specifications, solutions and customization options of pharmaceutical processing equipment for fruits and vegetables... Welcome you to visit our factory!

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu